PE Film Perforating & Rewinding Machine

Product Overview

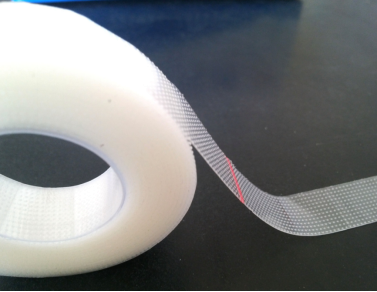

The PE Film Perforating & Rewinding Machine delivers consistent, high-quality perforations for medical and packaging films. Engineered for efficiency and reliability, this system features:

✔ Thermal Perforation Technology – Heated roller ensures clean, uniform holes

✔ Precision Tension Control – 10kg magnetic powder brake/clutch system

✔ Automated Web Guidance – Photoelectric edge alignment for perfect winding

Ideal for:

Medical film packaging (breathable films)

Food packaging (vented films)

Agricultural films (drip irrigation)

Key Features & Benefits

1. Advanced Perforation System

Heated Roller Technology:

Thermal oil circulation for even heating (±1°C accuracy)

Consistent hole quality across entire web width

Adjustable Speed: 5-40 MPM (variable frequency drive)

2. Precision Web Handling

Tension Control:

Unwind: 10kg magnetic powder brake

Rewind: 10kg magnetic powder clutch

Automatic Edge Alignment:

Photoelectric sensor for ±0.5mm accuracy

3. Robust Construction

Compact Footprint: 2150×1260×1400mm

Low Power Consumption: 10-15kW

Easy Maintenance: Quick-access components

Technical Specifications

| Parameter | Specification | Industry Advantage |

|---|---|---|

| Max Speed | 40 MPM | 25% faster than standard |

| Perforation Consistency | ±0.2mm | Superior hole uniformity |

| Roll Diameter | 600mm | Larger capacity |

| Power | 10-15kW | Energy-efficient operation |

Applications

Medical Films: Breathable surgical drapes, adhesive backing

Food Packaging: Perforated cling films, vented bags

Industrial Films: Agricultural covers, protective wrapping

Why Choose This Machine?

✅ Consistent Perforation – Thermal roller prevents uneven holes

✅ Easy Operation – User-friendly controls & minimal setup

✅ Durable Design – Built for 24/7 production